In pharmaceutical injectable filling line manufacturing, maintaining safety and sterility is crucial. Ampoule-filling lines fill ampoules quickly and cleanly, maintaining high production standards and ensuring efficiency. This blog will explain how ampoule-filling lines work and highlight their key features. We’ll also cover the latest advancements and important features in these systems used in modern Times.

what is Ampoule?

An ampoule is a tiny, airtight container utilized for maintaining the safety and sterility of liquids or gases, particularly in the pharmaceutical industry. It is a small, sealed vessel primarily composed of glass, used for storing medications, vaccines, or other essential substances. Sealed ampoules keep contents safe from air and pollutants until ready for use. There are various types of ampoules available, open and closed ampoules.

What is an Ampoule Filling Line?

An Ampoule filling and packaging line integrates multiple machines to ensure the precise and sterile processing of ampules containing liquid medications. Below are the key components of this line:

- Ampoule Washing Machine: Ampoules are washed with highly purified WFI (Water for Injection) to prevent contamination.

- Sterilization Process: Heat is used to sterilize the ampoule.

- Filling Station: Precisely fill each Ampoule with the specified dose.

- Sealing Mechanism: Seals the Ampoules by melting the glass tip.

- Inspection and Quality Control: Ensures each Ampoule meets quality standards.

The Importance of Ampoule Filling Lines in Modern Manufacturing

Ensuring Sterility and Safety:

Ampoule filling lines prevent contamination, ensure medication safety by operating in sterile environments, and use advanced sterilization processes. Each ampoule undergoes rigorous cleaning and sterilization before filling, preventing impurities from compromising the medication. Our lines feature modern Sterilization & Depyrogenation Tunnels, which use high temperatures (350°C) to eliminate microbial contaminants and pyrogens. This meticulous approach ensures every Ampoule meets the highest cleanliness standards, protecting patients and consumers from potential harm by maintaining the integrity and sterility of the products.

Compliance with Regulatory Standards

Our machines are compliant with the standard regulations required in pharmaceutical manufacturing. We customize our products to comply with FDA and EMA regulations.

CE Certification

- Council Directive 2006/42/EC – Machinery Directive

- Council Directive 2006/95/EC – Low Voltage Directive

- Council Directive 2004/108/EC – Electromagnetic Compatibility

Additionally, the system integrates with SCADA (Supervisory Control and Data Acquisition) and complies with the FDA’s 21 CFR Part 11 regulations. This integration ensures data accuracy and security, maintains detailed records, supports electronic signatures, and has strong access controls. By adhering to these standards.

Reduction of Contamination Risks

We reduce contamination risks by operating in sterile environments. Our cleanroom equipment ensures clean conditions with advanced filtration and sanitization technologies. By incorporating both open Restricted Access Barriers (oRAB) and closed Restricted Access Barriers (cRAB), we maintain strict control over contamination sources. This approach not only prevents contamination but also maintains high product quality and protects the integrity of our products.

Key Features to Look for in an Ampoule Filling Line

When selecting an Ampoule filling line, consider these essential features:

Speed and Efficiency:

| Ampoule Line | Ampoule Fill-Volume | Output (Ampoules per minute) |

|---|---|---|

| Ampoule Line 20 | 1ml | 20 |

| Ampoule Line 50 | 1ml | 50 |

| Ampoule Line 120 | 1ml | 100 |

| Ampoule Line 200 | 1ml | 200 |

| Ampoule Line 300 | 1ml | 300 |

| Ampoule Line 400 | 1ml | 400 |

| Ampoule Line 600 | 1ml | 600 |

Our machines accommodate diverse production volumes, delivering customizable speeds to meet specific needs. Whether you require the robust performance of our Ampoule Line 600, capable of processing up to 600 ampoules per minute, or the precision of our Ampoule Line 20 for smaller batches, we ensure optimal efficiency to match your production goals.

Open and Closed Ampoule Filling and Sealing

Our ampoule-filling machines precisely handle both open and closed ampoules. For open ampoules, the machine directly fills them without additional processing. For closed ampoules, our system first opens the ampoule, fills it with the desired product, and then seals it securely.

Versatile Machines with Change Parts

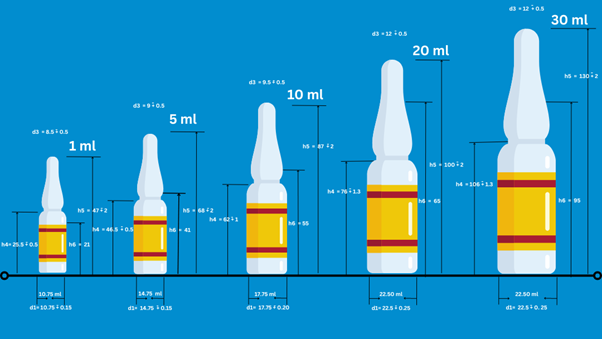

We offer ampoule filling machines that come with change parts for different ampoule sizes, including 1ml, 2ml, 3ml, 5ml, 10ml, and 20ml. This means you can easily switch between sizes to meet different production needs. Our machines make it simple to adjust for various ampoule sizes, ensuring efficient and effective production without needing separate machines for each size.

Precision and Accuracy with (100% check weighing systems for 20ml ampoules and larger)

100% check weighing systems ensure precise filling of each ampoule. This technology continuously monitors the fill volume, maintaining consistent and precise amounts, especially for 20ml ampoules and larger. The system features a “No Ampoule, No Fill” mechanism, preventing filling without an ampoule and reducing waste.

Filling Range

We offer ampoule filling machines that can fill from 1ml to 30ml, providing flexibility to handle different product needs accurately and consistently.

The Ampoule Filling Process Step-by-Step

1. Ampoule Rotary Washing Machine:

This machine is used at the beginning of the process to clean Ampoule thoroughly. It goes through a 6-step process to wash and rinse the ampoules, which includes:

Recirculated Water & Air:

First, the ampoules are washed with recirculated water and then blown dry with compressed air.

Purified Water & Air:

Next, they are rinsed with purified water and dried again with compressed air.

Water For Injection (WFI):

In the final washing step, the ampoules are cleaned with pure water known as Water For Injection.

Air Drying:

Finally, the ampoules are thoroughly dried using compressed air.

2. Sterilisation & Depyrogenation Tunnel:

- After washing, the Ampoule pass through this tunnel for sterilization and depyrogenation. This tunnel is divided into three parts, Dry Zone, Hot Zone and Cool Zone

- Drying zone: The ampoules are dried to remove the residual water left inside the ampoules.

- Heating zone (sterilization): The ampoules are sterilized & depyrogenated by heating them to a temperature greater than 300 °C.

- Cooling Zone: This is where the temperature of ampoules is brought down to room temperature.

This process ensures that the ampules are free from any viable microorganisms.

3. Ampoule Filling Line:

The core of the process is where the cleaned, sterilized, and depyrogenated Ampoules are filled with the liquid product. The process begins with ampoules being fed through a conveyor belt to the filling and sealing machine.

The ampoule filling machine operates in a controlled environment, either within an Orabs (Open Restricted Access Barrier System) or Crabs (Closed Restricted Access Barrier System). A precise pump fills each ampoule with the correct liquid amount, while nitrogen injection before and after filling protects the product.

4. Sealing Mechanism:

Filled ampoules are sealed at the sealing station by melting the glass tip to create an airtight seal. The sealing station has burners that preheat the ampoule tip and then seal it. Mixing oxygen and LPG gas generates flames for sealing.

5. Rotary Sticker Labelling Machine:

Once filled and sealed, the ampoules are passed through a rotary sticker labelling machine. This machine applies labels with essential product information such as dosage, batch numbers, expiry dates, and barcodes for traceability and regulatory compliance.

Snowbell Machines Ampoule -filling Line

At Snowbell Machines, we are proud to offer advanced ampoule-filling solutions tailored to the unique needs of manufacturers. Our lines use the latest technology to ensure sterility, accuracy, and efficiency. We have the knowledge and tools to boost your production, with custom solutions that fit perfectly into your process. Visit Snowbell Machines to learn more

Conclusion

Ampoule filling lines play a crucial role in pharmaceutical injectables Filling Machine manufacturing, ensuring that products are sterile, safe, and meet high-quality standards. From understanding the different types and key features to exploring the latest innovations and overcoming common challenges, this blog provides a comprehensive overview of ampoule filling lines. Investing in the right equipment not only enhances production efficiency but also ensures compliance with regulatory standards and improves overall product quality.